Our mission

We are passionately committed to making the production of fiber-reinforced lightweight materials more accessible and economical. With our idea, an intelligent computer-aided design system (CAD system), we want to design the entire production facilities for composite materials at the touch of a button!

In developing the customized software, we are initially focusing on the production of fibre-reinforced profiles using the pultrusion process. We address the following points:

Procuction costs

Reduction of up to 50% in the development costs of fibre-reinforced materials

Set-up time

Reduce the set-up time of pultrusion systems by up to 25 %.

Complex profiles

Enabiling production of complex profiles that were previosily not possible.

Our Expertise

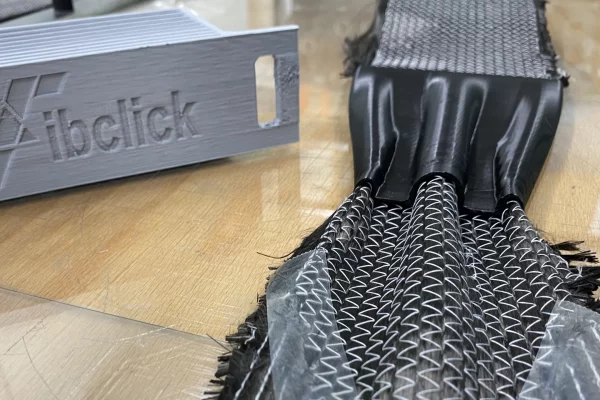

AI-based and 3D-printed forming tools

By simulating the course of the textile, a 3D model of a forming tool can be calculated. Depending on the complexity of the profile, such a forming tool can only be designed with conventional software with an immense amount of work due to the necessary free forms. Thanks to the 3D printing process, the complex tools can be produced cost-effectively.

By simulating the course of the textile, a 3D model of a forming tool can be calculated. Depending on the complexity of the profile, such a forming tool can only be designed with conventional software with an immense amount of work due to the necessary free forms. Thanks to the 3D printing process, the complex tools can be produced cost-effectively.

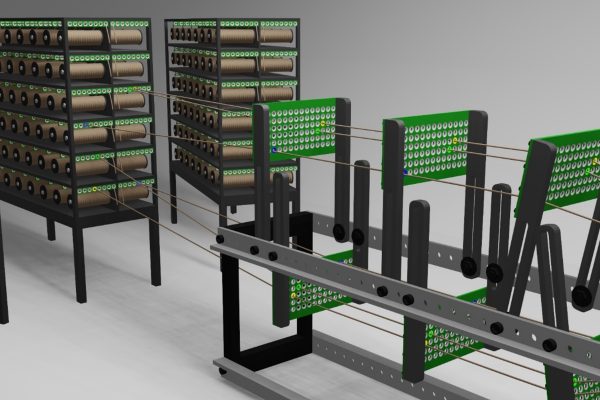

AR-based threading aid

We develop software that creates an optimised fibre guide plan in which the fibres are guided through several fibre guide plates without collision. This approximates the shape of the desired profile to ensure even fibre distribution. As the course of the fibres is now digitally available, step-by-step instructions for threading the fibres can be displayed in the employee’s field of vision using AR glasses.

We develop software that creates an optimised fibre guide plan in which the fibres are guided through several fibre guide plates without collision. This approximates the shape of the desired profile to ensure even fibre distribution. As the course of the fibres is now digitally available, step-by-step instructions for threading the fibres can be displayed in the employee’s field of vision using AR glasses.

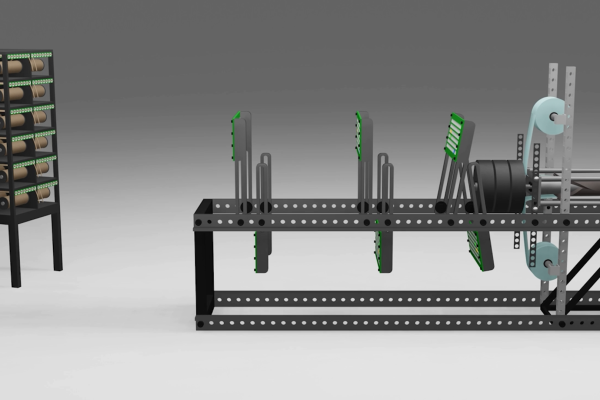

Automatically generated assembly plans

We use an optimisation process to calculate a construction plan that aims to achieve optimum component quality. Based on the component geometry and the component properties, a CAD design file is generated iteratively, taking into account the physical and design-related boundary conditions.

We use an optimisation process to calculate a construction plan that aims to achieve optimum component quality. Based on the component geometry and the component properties, a CAD design file is generated iteratively, taking into account the physical and design-related boundary conditions.

About us

Developing a Software-as-a-Service (SaaS) solution for a more efficiant production of fibre-reinforced lightweight materials is our highest priority. We are ready to start into a new chapter of designing complex composits with one full service solution!

Our partner

Our partner